portable ethylene analyzer

The F-900 Portable Ethylene Analyzer provides measurements of ethylene in real time. Quality Assurance professionals use the F-900 to collect the data they need to manage ethylene gas accurately and efficiently—in controlled atmosphere facilities, cold storage, and shipping containers. Until recently, sensitive ethylene measures were available only through complex and expensive gas sampling and gas chromatography analysis. The F-900 is an economical, yet precise, solution to ethylene measurement. The F-900 Research Kit enables the stand-alone unit to take in-situ measurements of ethylene flux from fruits and leaves non-destructively. By using the Injection Port Kit, users can take small-volume, point-in-time measurements ofethylene. Additional sensors for measuring CO2and O2can be added TOT and F-900 for complete ripening gas analysis. |

|

|

Features |  |

|

Specifications |

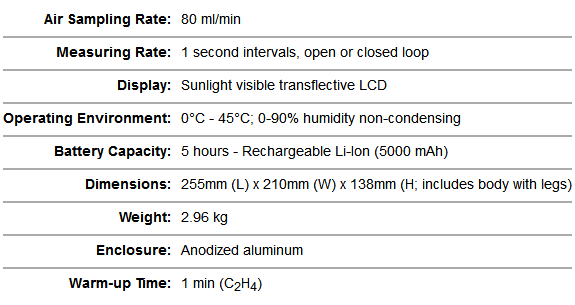

main unit

|

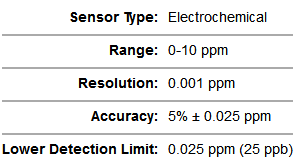

C2H4PP B sensor

|

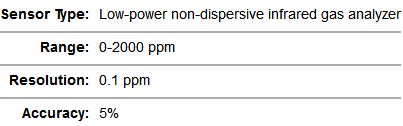

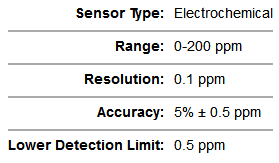

C2H4ppm sensor  |

co2ppm sensor (optional)

|

co2PCT sensor (optional)

|

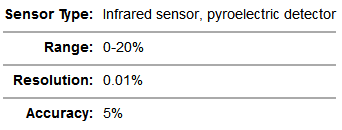

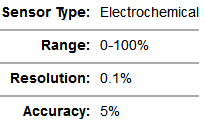

O2sensor (optional)

|

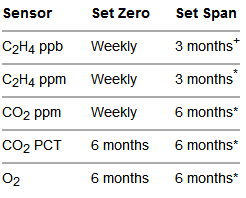

calibration schedule |

|

* standard gas required +typically < 5% per month |

uses |

|