German UIT company mainly provides bioreactors and biogas test equipment and various solutions, and is committed to providing high-quality and reliable equipment to help customers optimize biogas production, analysis, and R&D process flow.

Technical Features

Different reactor sizes can range from 5 to 1000 liters

Equipped with online measurement technology (gas quantity, gas mass, pH value, redox, temperature, etc.)

Equipped with silicon heating pads and a powerful agitator system

SENSOcontrol data acquisition and control system allows connection of UIT tube pumps for pH control or eccentric screw pumps for inlet and discharge

Measurement data can be stored in SENSO web-Cloud and accessible worldwide

Adopting a modular design, the number of reactors and the total working volume are very flexible, and other sensors can be selected to monitor various parameters.

Almost all measurable sensors can be added in subsequent tests, providing tailored solutions

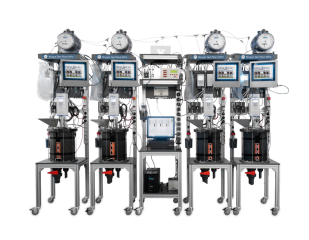

BT P2 Biogas testing equipment BTP2 is the basic system for matrix testing and gas potential testing. Working volume of glass reactor: 5 liters, 15 liters, 30 liters, 60 liters The continuous operation of the equipment is achieved through automatic feeding function Electric heating Double-layer stirrer with airtight shaft Binding pump for pH control Gas bags that collect gas samples Continuous monitoring of pH, temperature and redox potential, as well as measuring gas volume SENSOcontrol with touch screen Bracket system

|  |

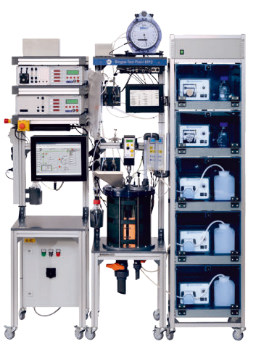

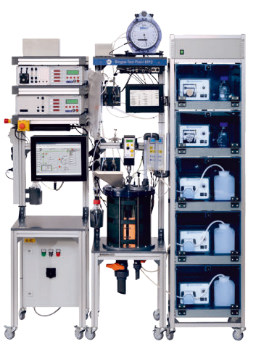

BT P2 analyzer Biogas testing equipment BTP2 ANALYZER is the first upgraded version of BTP2, mainly used for research on actual matrix or gas potential testing The BTP2 ANALYZER is equipped with a gas mass analysis module (CH4, CO2, H2S, O2 and optional H2), which cannot be expanded with additional reactors compared to the BTP2 control system. Working volume of glass reactor: 5 liters ~ 1000 liters The continuous operation of the equipment is achieved through automatic feeding function Electric heating Double-layer stirrer with airtight shaft Binding pump for pH control Gas bags that collect gas samples Measuring equipment: - Gas quantity

-pH/redox/temperature -Gas mass measurement system |  |

BT P2 volumes 90-10001 The BTP2 biogas test equipment is used for matrix testing, gas production testing and process optimization, with 400 liters and 1000 liters reactors used for pilot tests. The system is equipped with a wide range of online measurement technologies (gas quantity, pH value, temperature) Working capacity of stainless steel reactor (equipped with silicone heating pad): 80 liters, 120 liters, 150 liters, 400 liters, 1000 liters The continuous operation of the equipment is achieved through automatic feeding function Electric heating: T-control heating control system, which can automatically set the target temperature in the reactor with high accuracy Double-layer stirrer with airtight shaft Binding pump for pH control: SENSOcontrol data acquisition and control system can be connected to the UIT pump module to achieve pH control in the reactor The reactor can be expanded by gas analyzer Gas bags that collect gas samples Measuring equipment: - Gas quantity

- pH / redox / LDO / temperature - Gas mass measurement system |  |  |

s en so control General automation system SENSOcontrol is used for data acquisition applications and control of test devices (pumps, agitators) The system integrates an intuitive touch screen, which facilitates users to set parameters and display measurement data in real time Data storage Control:-Agitator

- pH control pump - Feed pump and discharge pump |  |

BTP2-CONTROL (with pump module)

Pipe pump for controlling pH and feed/discharge

Available tube pumps: SP4 and SP5

High-quality pump with 6 axes—SP4/high-quality pump with 3 axes—SP5

The suitability of the pipe pump SP5 (feed/output) depends on the matrix

The following functions of the pipe pump are controlled by SENSOcontrol:

- Asynchronous time control of feed and discharge

- pH-control control system

Basic pump cabinet with doors and separate containers

Can be used as a delivery pump for two-stage fermentation test

A single BTP module can also be equipped with a pump module; the pump module is controlled by SENSOcontrol

Pump module These pumps are perfectly combined with SENSOcontrol data acquisition and control systems, especially for UIT biogas testing equipment These pumps are equipped with stepper motors, so they meet the highest accuracy requirements and are suitable for continuous operation pH control software can set the desired pH value and control parameters Feed control software, which can set pumping time and interval time (asynchronous time control) Feeding control software, which can set pumping time and interval time (asynchronous time control) Storage and visualization of pumping sequences

|  |

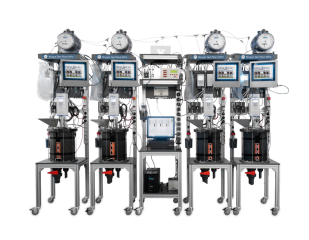

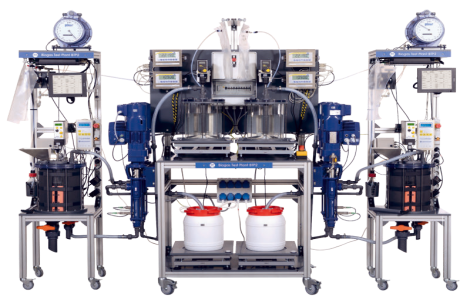

BTP2-CONTROL automatic biogas testing equipment The system can be used in combination with UIT's AS2 pump module and autosampler, with high equipment and automation BTP2 controlled biogas testing equipment is mainly used in scientific fields, but can also be used in matrix and gas production testing in other applications. A gas mass measurement system can connect up to 10 bioreactors 15 liter glass reactor, available in different volumes upon request Continuous operation through automatic feeding Electric heating; optional cooling Silicon heating belt Double-stage agitator with airtight shaft Dispensing pump for pH control Gas bags for collecting gas samples Measuring equipment: - Gas quantity

- pH/redox potential (optional)/temperature - Gas mass measurement system (CH4, CO2, H2S, O2) Automatic gas analysis system Biogas control software package SENSOcontrol with touch screen

|  |

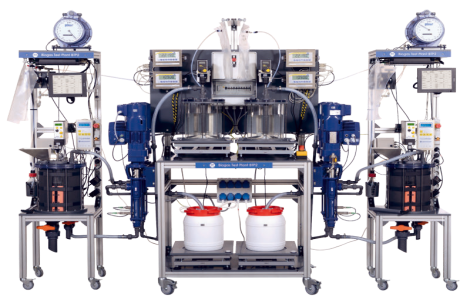

BTP2 with feed system BTP 2 with feed system for accurate feeding by using eccentric screw pumps and scales BTP2 includes feed pump and discharge pump To meet the requirements of the automatic feed/discharge system of biogas testing equipment, UIT has equipped the biogas testing equipment with a powerful eccentric screw pump or peristaltic pump. Eccentric screw pump is suitable for larger conveying volumes and particle sizes Solid content size: 6 mm - Maximum fairway cross-section - Other maximum solid sizes available upon request Maximum fiber length: 30 mm - Other maximum fiber lengths available upon request Rated flow rate 51 liters/h with additional frequency converter for changing flow (minimum 20 liters/h) External ventilation of the inverter – required when using the minimum range of the pump (5 liters/hour) The system is equipped with a weighing pan to accurately display feed results Control the pump module and scale module via SENSOcontrol: - Asynchronous time control for feeding and discharge

- Weighing monitor |  |

BTP2-STERILE modular bioreactor Bioreactors are sterilizable 5/8/10 liters of glass reactors of different volumes, other sizes available upon request Double wall reactor (topped) or no top reactor Agitator with airtight shaft Heating and cooling of reactors Dispensing pump for pH control/feed/output Gas inlet for 3 types of gases, equipped with mixing device and a mass flow controller Measuring equipment: - pH/LDO/Redox/Carbon dioxide/Cell density temperature

- Gas mass measurement system (optional) |  |

| GAS QUALITY Gas mass measurement technology - CH4 0...100 vol % Infrared sensor - CO2 0...100 vol % IR sensor - O2 0...25 vol % Electrochemical sensor - H2S 0...5000 ppm Electronic chemical sensor - H2 0...2000 ppm1) Electrochemical sensor - H2 0...100 vol%1) Thermal conductivity sensor |  |

|

BTP-100 pilot equipment/pilot container Pilot equipment used in biotechnology applications can be customized completely according to customer requirements Biotech pilot equipment can provide innovative, high-performance and safe bioprocess solutions for a variety of applications Pre-fermentation and post-fermentation processing equipment and storage solutions can be realized in containers The reactor size can reach 1000 liters; steel reactor Electric heating of bioreactors Feed pump and discharge pump Dispensing pump for pH control Measuring equipment: - Gas mass

- Quantity of gas - Mass flow controller - pH/Redox/Temperature |  |

Pilot vessel - Biogas (BTP2-control with pump module)

Biogas pilot container is a transportable solution tailored for pilot-scale biogas testing equipment

The pilot container will be customized completely according to customer requirements

Pilot containers can be used for dry/wet fermentation, can also meet the requirements of filtration, and can be operated continuously or in batches.

Complete container equipment (air conditioning, electrical equipment, etc.)

Stainless steel bioreactors with different working volumes

Automatic feeding and discharge

Electric heating

Dosage pump for pH control

To ensure health and safety, the test equipment is equipped with a gas alarm system

Measuring equipment:- Gas quantity

- pH/Redox/Temperature

- Gas mass measurement system

SENSOcontrol with touch screen

By design, the test equipment is installed in a CSC-compliant 20-foot sea shipping container

Pilot container-Biotechnology Pilot containers for biotechnology applications can be customized and manufactured completely according to customer requirements. Biotech pilot containers can provide innovative, high-performance and safe bioprocess solutions for a variety of applications Pre-fermentation and post-fermentation processing equipment and storage solutions can be implemented in containers Sterile bioreactor with stirrer Complete set of container equipment (air conditioning, electrical equipment, gas alarm system) Electric heating of bioreactors Ingredient pump Measuring equipment: - Gas mass

- Mass flow controller - Quantity of gas - pH value/redox value/temperature |  |

Application areas

Provide standardized and customized laboratory testing facilities for biogas research, product development (enzymes, nutrients), process optimization and biotechnology

Comparison table of several models

| BT P2 BASIC | BT P2 | BT P2 analyzer | BT P2 control | B TP sterile | pilot plant |

Reactor volume |

|

|

|

|

|

|

5l | √ | √ | √ | √ | √ |

|

15/30/60l | √ | √ | √ | √ | Optional |

|

90-1000L, stainless steel |

|

|

|

|

| √ |

Electronic heating system, including temperature controller | √ | √ | √ | √ | √ | √ |

Suitable for disinfection |

|

|

|

| √ |

|

Mixer, including airtight shaft feedthrough |

|

|

|

|

|

|

Airtight shaft feedthrough | √ | √ | √ | √ | √ | √ |

Axis feedthrough | √ | √ | √ | √ | √ | √ |

Suitable for asynchronous operation of mixers | √ | √ | √ | √ | √ | √ |

Measuring instruments |

|

|

|

|

|

|

Gas quantity (gas tank counter or Milli gas counter) | √ | √ | √ | √ | Optional | √ |

Automatic gas mass measurement (CH4, co2, H2S, O2) |

|

| √ | √ | Optional | √ |

•Use measurement for up to 8 reactor unitsMeasuring instrument |

|

|

| √ | Optional | √ |

•Measurement of H2 in gas phase |

|

| Optional | Optional | Optional | Optional |

Air pressure sensor |

|

| √ | √ | Optional | Optional |

Substrate pH measurement | √ | √ | √ | √ | √ | √ |

ORP measurement in substrate |

| Optional | Optional | Optional | Optional | Optional |

Measurement of dissolved carbon dioxide in substrate |

| Optional | Optional | Optional | Optional | Optional |

Inside the reactor temperature | √ | √ | √ | √ | √ | √ |

Gas temperature | √ | √ | √ | √ | Optional | √ |

The speed and torque of the mixer | √ | √ | √ | √ | √ | Optional |

Water supply and drainage pumps |

|

|

|

|

|

|

Pipe pump | Optional | Optional | Optional | Optional | Optional | Optional |

Eccentric screw pump | Optional | Optional | Optional | Optional |

| Optional |

SENSO control - Data storage, visualization and control |

|

|

|

|

|

|

SENSO control includes touch screen |

| √ | √ | √ | √ | √ |

PH control-automatic pH setting |

| Optional | Optional | Optional | √ | Optional |

OPR Control |

|

|

|

| Optional |

|

Automatically trigger feeding |

| Optional | Optional | Optional | Optional | Optional |

Control of additional pumps |

| Optional | Optional | Optional | Optional | Optional |

Torque measurement, not in BTPsterile |

|

|

|

|

|

|