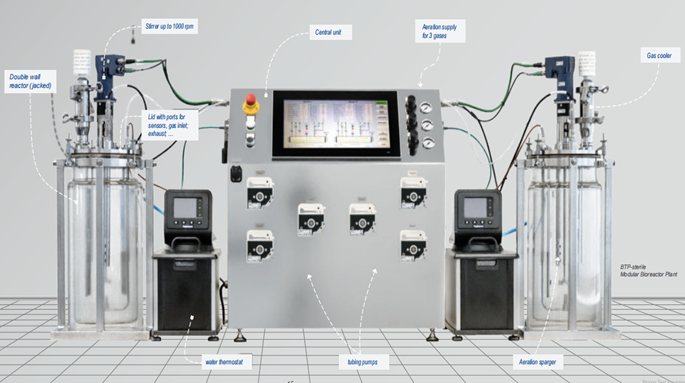

The BTP sterile reactor is made of glass and stainless steel so that the bioreactor can be disinfected (autoclaved) before the experiment begins.

The BTP system is characterized by basic equipment, such as: sensors, SENSO controllers, pH control pumps, and optional feed and discharge pumps.In addition, 3 gases can be input into the bioreactor, for which the valve matrix can be used, and the entire volume flow is controlled by the mass flow controller.

Technical Features:

1. Bioreactors are sterilizable

2. 5/8/10 liters of glass reactors with different volumes, other sizes are available upon request

3. Double wall reactor (topped) or no top reactor

4. Agitator with airtight shaft

5. Heating and cooling of the reactor

6. Batching pump for pH control/feed/output

7. Gas inlet for 3 types of gases, equipped with mixing device and a mass flow controller

8. Measuring equipment

- pH/LDO/Redox/Carbon Dioxide/Cell Density Temperature

- Gas mass measurement system (optional)

9. SENSOcontrol with touch screen

Equipment composition:

1. Basic unit: Sterile bioreactor

• Connection options for two bioreactors (UITs)

• Control unit with panel computer (15.6" true plane WXGA TFT LCD with projection capacitive touch controller; front panel with IP65 protection rating)

• Control software (such as Windows 10, integrated control unit for pipe pumps), pH control is part of the standard configuration

• Two individually controlled reactors: USB interface for data transmission; LAN interface

• Three types of gas input: suitable for pipes with a diameter of 6 mm

• Power supply 110-230 V AC with emergency shutdown switch

• Dimensions: 700 x 550 x 690 mm stainless steel housing

2. Control unit: SENSOcontrol

1) Control function:

• Agitator control (speed and asynchronous use)

• pH control (tube pump control)

• Aeration control

• Feeding system (pipe pump control)

• Reactor temperature control

2) Display and store:

• The flow chart of the current system, including the display of the current measured value

• Display the current measurement value in a table form

• Graphic display of main parameters

• Measured value storage

3. Pump:

• Each reactor can be equipped with up to 5 pump heads (SP4-S-UPPH5061)

• Total 10 pieces - Pump heads are suitable for pipes of various sizes (0.13 x 0.9 mm; 0.25 x 0.9 mm; 0.51 x 0.9 mm; 0.76 x 0.85 mm; 1.02 x 0.85 mm; 1.52 x 0.85 mm; 1.85 x 0.85 mm;2.06 x 0.85 mm; 2.54 x 0.85 mm; 2.79 x 0.85 mm)

• Flow rate 0.00014......41,52 ml/min A variety of pipe diameters are available

4. Bioreactor with stirring device:

• Version 1: Double-wall glass reactor - with jacket

• Version 2: Glass Reactor - No Jackets

• The maximum operating temperature of borosilicate glass/reactor is 60°C (other temperatures are available upon request)

• Glass reactor with stainless steel parts: autoclaved

• The cover is made of 316L stainless steel

• Airtight shaft through-piece with enhanced seal

• The speed of the stirring device can reach 0....1000 rpm; 200 W maximum torque 200 Ncm

• Mixing Tool: Rushton Impeller

• Includes baffle assembly

• Includes air aeration tube with porous nozzles

• Exhaust gas cooler

• Sterile filter

• The entire system bracket

5. Sensor:

1) Normal sensor:

• The sensor is autoclaved

• Diameter: 12 mm/process connection PG 13.5

• Internal temperature sensor NTC

• Interface: MODBUS-RTU/ Electrical connector: VP8

• Available length: 120/ 225/ 325/ 425 mm

2) PH sensor:

• Combined electrode: Measure pH potential according to reference Range: pH 0 to 14

• Sensitivity: 57 to 59 mV/pH at 25°C

3) ORP sensor:

• Combined electrodes: Measure ORP potential according to reference

• Range: -1500 to +1500 mV

• ORP component platinum ring

4) Dissolved oxygen – LDO sensor

• Range: 4ppb...25ppm DO (0...25mg/O2) 0 to 62.85%vol or 0~300% saturation

• Accuracy at 25℃: 1 +/- 0.05 %-vol; 21 +/- 0.2 %-vol; 50 +/- 0,5%-vol

• Measurement principle: oxygen quenching, temperature compensation

• Oxygen consumption: None

5) CO2 sensor:

• Measurement principle: non-dispersive infrared (NDIR) absorption of carbon dioxide; temperature compensation

• Range: 5-1000 mbar or 0.5-100 % vol or 7.5-1500 mg/l (liquid phase), pressure 101.3 kPa, temperature 15°C

• Accuracy at 25℃: +/-5 mbar (5-100 mbar); +/-5% (>100 mbar)

6) Conductance sensor:

• Range: 1 µS/cm to 300 mS/cm

• Accuracy at 25℃: +/- 3% at 1 µs/cm to 100 mS/cm; +/- 5% at 100 to 300 mS/cm

• Measurement principle: quadrupole contact type

• Battery constant: 0.36 cm-1

7) Total Cell Density Sensor (TCD)

• Measurement range: For example: 0-200 g/l cell dry weight yeast/0-4 AU/0-30000 NTU

• Accuracy at 25℃: Resolution: 0.05 g/l 0-10 g/l); 0.5 % (> 10 g/l) Dry weight yeast of cells

• Measurement principle: transmission and reflection (including temperature compensation, sunlight filter and dimming) near infrared wavelength 860 nanometers

6. Temperature control:

1) Thermostat/refrigeration circulator:

• 7 liters in volume/including circulator installed in the basin

• Includes a temperature sensor installed in a bioreactor

• 3.75-inch touchpad LCD display

• 230V AC power supply (other power supply is provided upon request)

• Maximum ambient temperature: 35℃

2) Heating/cooling - Temperature control through water

• The refrigeration circulator is controlled by the central control device

• Heater: 2200 watts

• Cooling capacity: 20°C, 200 W

• Internal pump Maximum 16.7 liters/min

• Variable pump speed - controlled by thermostat

• Maximum pressure: 0.25 bar

3) Heating - Use a thermostat heating system, temperature control through water pump technology (maximum target temperature 60°C)

• The thermostat is controlled by a central control device

• Internal pump Maximum 16.7 liters/min

• Variable pump speed - controlled by thermostat

• Maximum pressure 0.25 bar

• Heater: 2200 watts

• Maximum ambient temperature 35 °C

4) Heating pad

• Heating through an electric heating pad, with a maximum target temperature of 60°C, and other heating methods are provided upon request

• The heating pad temperature can be defined; the substrate temperature can be measured and the control system can be implemented

• The size of the heating pad depends on the size of the reactor

Application areas:

Suitable for product development (enzymes, nutrients), process optimization and biotechnology applications