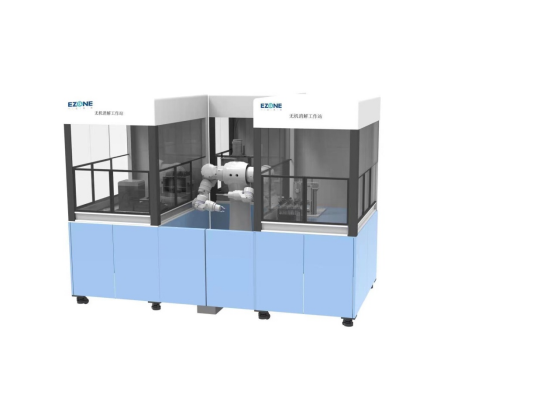

Product Overview

The inorganic pretreatment production line is a set of mechanized, automated and intelligent equipment that is specifically designed for the pretreatment process of various inorganic projects.It includes 6 hardware modules: "weighting module, digestion module, handling module, filtering pipetting module, volume control module, and safety signal module".The production line is equipped with a double-arm robot to complete the processes of weighing, loading, handling, acid addition, digestion, cooling, volume setting, shaking, filtration, waste liquid treatment, etc., and the action completion effect is consistent with manual operation.

The production line is equipped with special application software to manage the operation of all functional modules on the production line, including status acquisition, data storage, equipment debugging and maintenance reminders.

Application areas

In the fields of environmental testing, food testing, pesticide residue testing, textile testing, consumer goods testing, material testing, etc., inorganic testing of solid, semi-solid and liquid samples, such as pre-treatment of heavy metal projects.

Performance Features

hardware

1. A two-arm robot that completely simulates manual operations, and the experimental actions are consistent with the standard requirements;

2. The double-arm robot has stable performance and accurate positioning;

3. The entire process is automated, and can work continuously for 7×24 hours, with high processing efficiency;

4. Solid, semi-solid and liquid samples can be processed;

5. Each module can be used in integrated production lines to process samples, or can be used alone or in combination of any module;

6. Each module is designed with a channel unit. Each channel unit can be independently enabled and set parameters. The number of opening channels can be set according to the sample quantity to save reagents and energy;

7. The operation steps are carried out completely in accordance with the steps specified in the analysis standards, and the internal standard extraction and recovery rate of various samples is fully in line with the quality control requirements;

8. Sample transfer route design, action design, and sample processing sequence marking to effectively avoid cross-contamination;

9. Automatically detect the operating life of equipment components and reasonably plan the maintenance and warranty schedule.

software

1. The method can be edited and saved at will, fully complying with the conditions and requirements of the analysis method standards;

2. Modern and simple design, in line with mainstream operating habits;

3. Unique graphical programming, the editing method is simpler and more intuitive;

4. The system adopts a B/S architecture, with good scalability, and automatic background upgrades do not require user operations;

5. Use network cable to connect, and the communication is stable;

6. The operation logic is simple and the learning time is very short

7. Support remote upgrade of robot firmware, making maintenance more convenient

8. The original experimental records can be exported and printed, and the processing process information is clear at a glance, which facilitates record preservation and traceability;

9. Custom user permissions can be customized for easy management;

10. The system port is open and can be connected to the LIMS system to realize laboratory information sharing.

Production line process (the module sequence can be adjusted according to project standard steps)

Technical parameters

Model specifications | Weighing module |

Balance weighing range | 0.0001~120 |

Sample Type | Solid powder |

Model specifications | Dissolve module |

Maximum power | 3000W |

Number of holes | 42-bit, 84-bit |

Kong Shen | 50 Mom |

Ore diameter | 30 Mom |

Temperature range | Room temperature ~260℃, room temperature ~420℃ |

Heating method | Electric heating tube heating and high-density graphite conduction |

Heating material | Special high temperature materials |

Heat up rate | 10℃/min |

Temperature uniformity | ±2℃ |

Digestion pipe material | PTFE/Quartz |

Digestion tube volume | ≤50ml |

Pipe material | PF A |

Model specifications | Two-arm robot |

Degree of freedom | fifteen |

Positioning accuracy | ±0.02mm |

Working speed | 50 Mom/Yes |

Driver method | Electric power drive |

Control method | Servo control |

Model specifications | Filter module |

Pipeline Accuracy | ±0.5mL |

Model specifications | Configuring module |

Capacity accuracy | ≤0.1% |