VELP is one of the early manufacturers to develop and produce Dumas nitrogen detergent instruments, so it has a deep foundation in the element analyzer industry.Elemental analysis is the preferred technique for quantitative determination of organic CHNS/O in samples by oxidation and pyrolysis.Analysis of carbon, hydrogen, nitrogen, sulfur and oxygen helps determine the structure of unknown compounds, as well as assessing the structure and purity of synthetic compounds.Elemental analysis can obtain a lot of information from the sample.

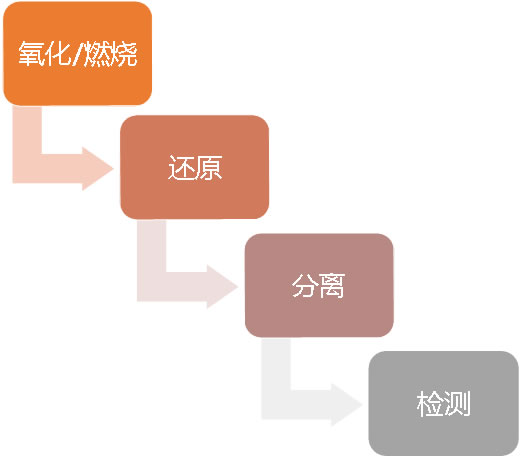

How element analyzer works

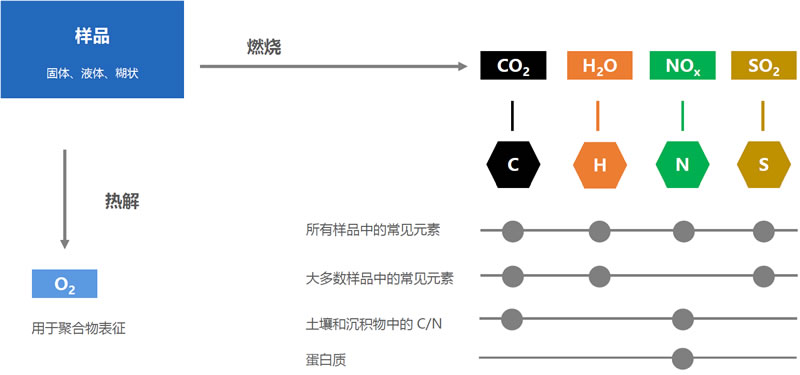

combustion

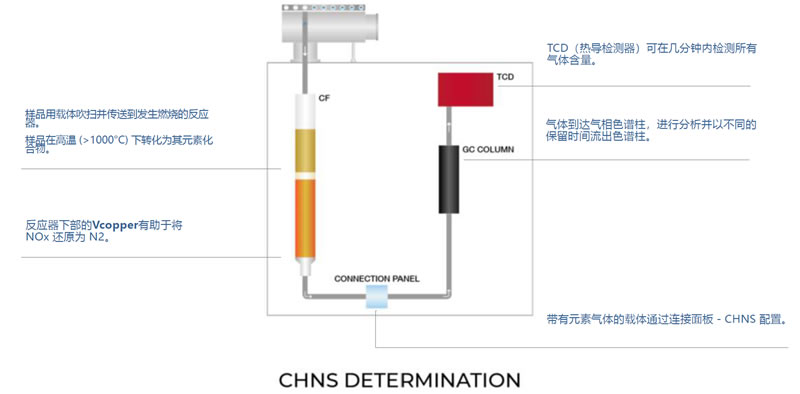

After weighing and removing the atmospheric gas, it is heated in a high temperature furnace and burns rapidly in the presence of pure oxygen at about 1000°C.This leads to the release of substances such as carbon dioxide, water, nitrogen dioxide, sulfur dioxide, etc., and most importantly, nitrogen is in several oxides (N)SmallOhave) is released.

Sample + O2→ CO2+ H2O + NSmallOhave+ so2+ O2+Other oxides

Restore and separation

Collect the combustion products and balance them.The gas mixture is passed through hot copper to remove any oxygen and converts the nitrogen oxides into molecular nitrogen.The gas is separated through the column.

co2+ H2O + NSmallOhave+ so2+ O2+Copper → CO2+ H2O + N2+ so2

Test

The sample signal from the thermal conductivity detector can then be converted to the total nitrogen content.The calibration curve can be created in the software using standard (EDTA/sulfonacid) to convert the signal received from the TCD into mgN.

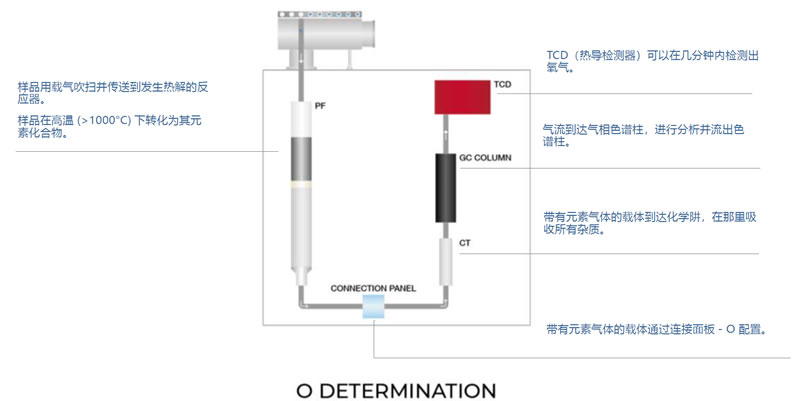

*O Determination: The sample enters the pyrolysis tube, undergoes high-temperature pyrolysis to generate CO, and passes through a special chromatographic column for O element, and is detected through a thermal conductivity detector.

Principles of CHNS-O element analysis

EMA 502 Element Analyzer

All-in-one compact solution

Important points

● All-in-one compact solution for CHNS-O assays;

● No additional modules are required, and the carrier gas selection is flexible;

● Enhanced versatility and productivity;

● Quick changes to electronic autosamplers, microbalance connections and configurations;

● Excellent accuracy and accuracy use TCD and GC columns;

● EMASoft software with new user interface is unparalleled ease of use;

● Improve workflow with VELP Ermes: Remote support and access to instrument conditions and data.

The EMA 502 Element Analyzer is used to determine carbon, hydrogen, nitrogen, sulfur and oxygen in various industrial fields such as pharmaceutical and life sciences, organic chemistry, petrochemical and energy, environment, agriculture, food and feed.Solution.

model

● CHNS determination

● O Determination

The EMA 502 does not require any add-ons or additional external modules.The dual carrier gas is selected for helium for CHNS-O or argon for CHN analysis.

Versatility and productivity

● EMA 502 is designed for unattended work in 24/7 365 days a year, and provides quick and easy daily maintenance;

● EMA 502 processes up to 117 samples at a time, which is extremely efficient;

● Electronic autosampler, microbalance connected to the PC to directly transmit weighing data;

● Easily perform CHNS analysis and switch to O mode in a few steps: replace the gas chromatography column, replace the reaction tube, adjust the connections in the connection panel.

Stability and accuracy

● The EMA 502 is a flexible and powerful analyzer designed for excellent reliability and excellent accuracy;

● The gas chromatographic column thermostat ensures uniform and modular temperatures, which completely separates all elements for final detection by TCD;

● TCD detection technology ensures extremely accurate and repeatable results, with an RSD value of 0.2% (sulfonacid).

Easy to use and data security

EMASoft software is a powerful VELP solution that controls and operates the EMA 502 element analyzer.EMASoft comes with a user-friendly interface that displays all relevant information at a glance.

Features:

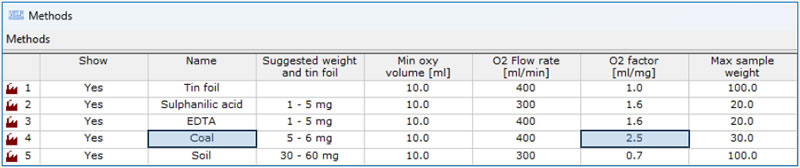

●Creation of preinstalled method libraries and custom methods

● Analysis is only available in a few clicks

● Use animation tutorial to change configuration

● Real-time chart displays gases detected by TCD

● Maintenance menu for sending alarms when reactors are almost exhausted

● The result table shows the average, SD and RSD of the analysis and selects it directly on the chart

The EMA 502 software can be upgraded with the optional 21CFR Part11 software package and is suitable for laboratories that require FDA compliance.

Ultimate support and complete workflow

The EMA 502 has unique connectivity options to the VELP Ermes cloud platform.

● Real-time monitoring and analysis of instrument status anytime, anywhere

● Instant Events and Alert Notifications

● Share information directly with VELP or authorized service centers to shorten diagnostic time and enhance service support for maximum system uptime

EMA 502 CHNS-O Element Analyzer

The advantages of innovative TEMS, four major savings!

Time Saving Save Time:

● Rapid heating and reduce waiting time

● Quickly change configuration CHNS|O

● Low maintenance (minimal design!)

● Only 1 reaction tube is required to burn/restore at the same time

● ermes cloud platform (faster service!)

Energy Saving Energy Saving:

● Low carrier gas consumption (only 140 ml/min!)

●Low energy consumption (570 W)

Money Saving Savings:

● Extremely low single sample operation cost

●Simple design = extremely competitive price

Space Saving Saves:

●Earth space (50 x 51 x 41 cm | 45 Kg)

Sample preparation

Several milligrams of samples are required for trace element analysis:

● Sample preparation and sample weighing are becoming increasingly important.

● A microbalance (6 digits after the decimal point) is required to achieve high precision and precision.

●Tin Foil Cup 5x9mm, 150 pieces (code A00000436)

In general, in CHNS analysis of quantitation of unknown substances, it is recommended to use less than 3 mg of samples.

For low carbon samples, EMA supports sample weight up to 100 mg.

EMA 502: CHNS configuration

EMA 502: O Configuration

Configuration changes

Change from CHNS to Oxygen configuration in just a few simple steps:

1. Put the instrument in standby mode and wait for the standby condition to be reached

2. Select Menu > System/Configuration/0

3. Replace the gas chromatography column (for A00000437 GC column of 02)

4. Replace the reactor

5. Change connection in the Connection panel

6. Put the instrument in working mode

Configuration changes have been performed.

Analysis starts with new working conditions → 30/35 minutes

※ The operation can be performed vice versa.

Supply and configuration

| F30800100 | EMA 502 Element Analyzer 230V150-60Hz |

Include:

● Startup kit for approximately 1000 CHNS analysis: catalyst, tin foil, standards, other required chemicals

● Tools and accessories for reactor preparation, reactor replacement, sample preparation, etc.

Standard configuration - CHNS

| E30800100 | fa 502 F-Mental analyzer 230V150-60Hz |

CHNS-O configuration

| F30800100 | elemental analyzer 230V/50-60Hz |

| A00000433 | kit approx.1000 analysis for O2 |

| A00000437 | GC column for O2.At any time.1 no |

Other accessories such as catalysts, reactors, etc.

| A00000432 | kit approx. 1000 analysis for CH NS |

| A00000438 | GC column for CH NS. PTFE.2 No |

Main parameters of the instrument

parameter | Ema 502 |

Analysis Methods | CHNS combustion O: pyrolysis; separation through chromatographic column, thermal conductivity detector (TCD) detection |

Sample injection volume | Up to 100mg (based on C content) |

Analysis time | CHNS: About 12 minutes; O: About 6 minutes |

Measible parameters | Test elements can be selected through software without measuring modules, CHNS, CNS, CHN, CN, N, S, O, etc., you can analyze which elements you choose through software. |

Detection limit | <50ppm (TCD) |

Accuracy | <0.2% |

Scope of analysis | Analysis range C 0.001 – 20 mg Helium as carrier gas; 0.01 – 20 mg Argon as carrier gas Analysis range H 0.001 – 5 mg Helium as carrier gas; 0.01 – 5 mg Argon as carrier gas Analysis range N 0.001 – 20 mg Helium as carrier gas; 0.01 – 20 mg Argon as carrier gas Analysis range S 0.01 – 6 mg Helium as carrier gas Analysis range O 0.005 – 6 mg helium as carrier gas (this parameter is better than other brands on the market) |

Combustion/pyrolysis temperature | CHNS: 1030°C; O: 1060°C |

Automatic sampler | Standard 1 automatic injection disc (30-bit), up to 4 injection discs, each injection disc 30-bit (up to 117-bit) |

Consumables | Integrated combustion tube and reduction tube, one tube can test samples 250 times.The cost of a single sample is extremely low. You can directly replace the entire tube or add filler separately. It is flexible in operation and low operating cost. |

Industry and applications

Elemental analysis provides reliable element content results for various application fields:

industry | application | sample | Application Cases |

Pharmaceuticals and Life Sciences | Determination of composition, structure and purity of organic chemicals | Blood, urine, raw materials, final products | Analysis of impurities in CHN in paracetamol, CHNS in hair or nails |

Organic Chemistry | Organic compounds in various materials are determined to ensure the characteristics and behavior of the final product, the composition structure and purity of the organic chemicals. | Polymers, rubber quality, graphene, new materials, coke photoresist, chemicals | CHNS in tires to evaluate organic synthesis CH ratios in vulcanization process |

Petrochemical and energy | Quality assurance and quality control of petrochemical products. | Fuel, lubricating oil, engine oil | CHNS in oil to evaluate impurities determined by S and calorific value |

environment | Detection of organic compounds. | Water, wastewater, compost and particulate matter emissions | CHNS in air and water filter sediments |

agronomy | Scientific analysis. | Soil, leaves, fertilizer | CHNS in leaves to determine the amount of contaminants |

Food and feed | Protein assays are used as a measure of quality and price setting; ensure compliance with the food ingredients statement.Sample preparation for isotope analysis (IRMS-isotope ratio mass spectrometry)** | Food, animal feed, raw materials, beverages | Sulfur in tomatoes to assess acid |

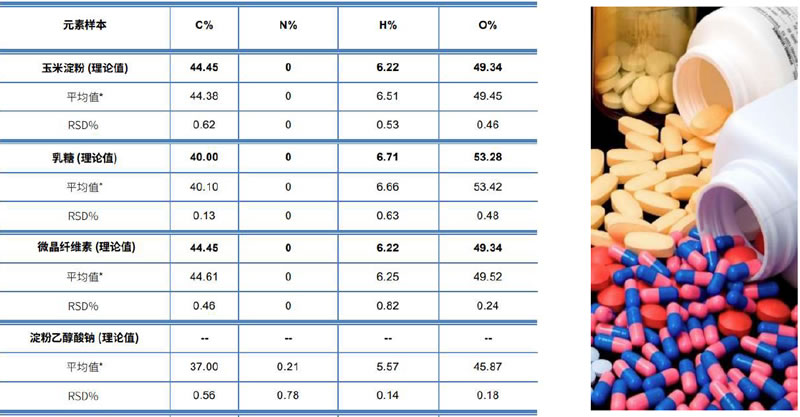

Pharmaceutical field

CHNS-O elemental analysis is applied to all stages of the pharmaceutical and chemical production process.Used to confirm the purity of raw materials and reagents before production.The purity of the product at each stage is then used throughout the process to maintain strict control of production and demonstrate quality control.

CHNS-O element analyzers are also widely used in the research and development stage, as well as compound structure analysis, magazine analysis, etc.

When the sample type is changed, the reproducibility is good and there is no memory effect.

Material Characterization

In the past, the main application of organic element analysis was to determine the chemical formula of organic compounds.Today, the determination of CHNS-0 by combustion method analysis can help ensure product quality control of many finished products (such as polymers and rubbers, depending on the quality of the raw materials used).

● University, Organic & Inorganic Synthesis (Institute of Chemical Sciences)

●Polymer industry (Tiqian, Viton, Tire...)

●High-tech new materials (glass, fibers, graphite, special polymers, etc.)

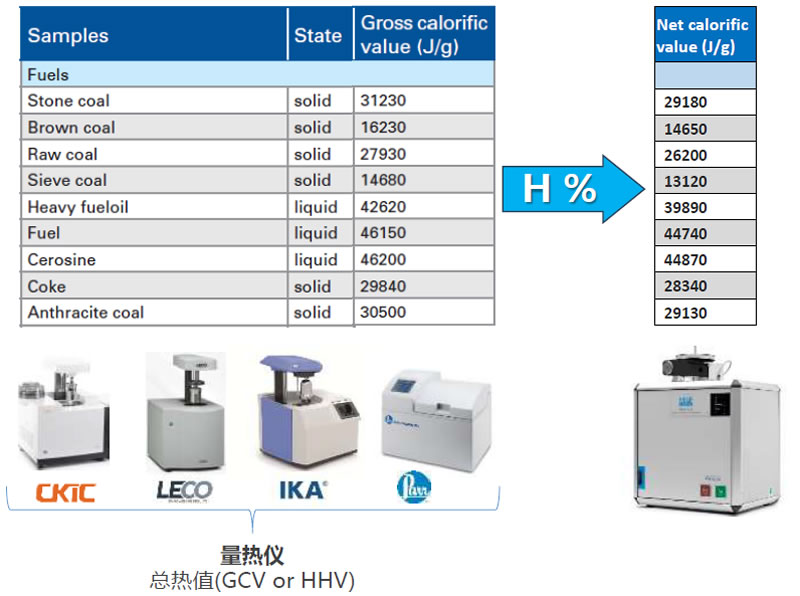

Energy sector

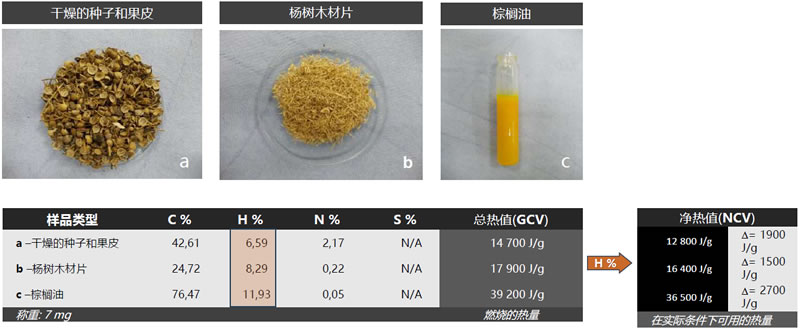

"Calculate net calorific value (NCV) using elemental analysis"

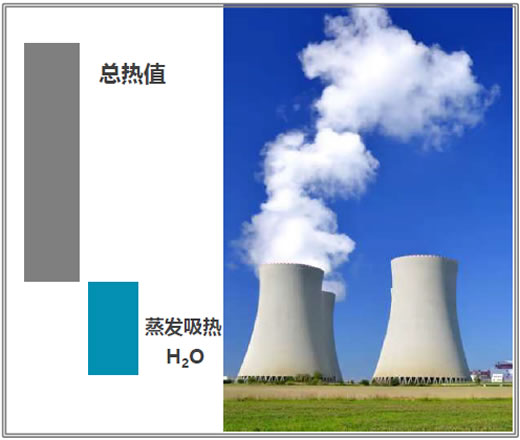

The total calorific value (GCV) represents the energy released as heat when the substance is completely burned, which is very variable in calculating the energy content (efficiency) of the fuel.Due to the evaporation (heat absorption) of the power plant, the energy value that can be actually used during the combustion process is called net calorific value (NCV).

NC V= GC V-(H [%] Small 9 Viewed) Small 2500 KJ

The hydrogen content in the sample was determined by elemental analysis, and a higher calorific value was measured using an isocyclic calorimeter, which obtained absolute accuracy.

Petroleum & Petrochemical & Coal

Elemental analysis has been established as a standard technique for fuel characterization.The determination of fuel calorific value is part of the quality control process and determines its market price.Determine the environmental compatibility and purity of fossil fuels, and is also used for renewable raw materials and efficiency in refinery production.

●Coal coke

● Oil crystals (mineral oil, crude oil, heavy oil)

● Liquid fuel (without diesel, gasoline or natural gas)

DIN 51724-3: Determination of solid fossil fuels, S, Part 3: Instrumental Methods

ASTM D5291: Test method for instrumental determination of carbon, hydrogen and nitrogen in petroleum products and lubricating oils.

ASTM D 5373: Standard test method for instrumentation for determining carbon, hydrogen and nitrogen in coal and coke laboratory samples.

Samples with high carbon content (90%) need more oxygen to achieve complete combustion and require special additives (V2O5) to improve recovery (such as sulfur and carbon).

Vanadium pentoxide (V2O5): Combustion aid, if carbon or sulfur is not optimal (such as coal/coke auspicious products).

Biomass fuel

Elemental analysis is important for quality control, and the results can be used as input parameters for the calculation of combustion of solid biofuels.The importance of the environment:

●Nitrogen: NOSmallEmissions

●Hydrogen: Calculate net calorific value

●Carbon: Determination of CO2Emissions

University and public laboratories: Biomass research team, Pellets research team

Biomass power plants: power plants, cement plants (whenever biomass is used as biofuels)

EN ISO 16948: 2015-Solid Biofuels-Determination of Total Carbon, Hydrogen and Nitrogen Content.

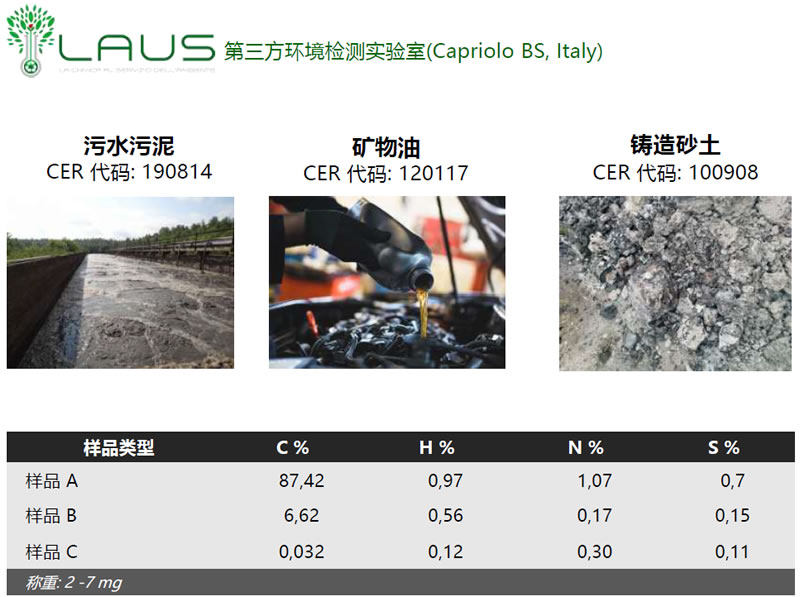

Waste (solid and liquid)

Solid Recycled Fuel (SRF) is fuel (a fossil alternative) generated from various types of high-energy waste such as urban solid waste, industrial waste or commercial waste.

●Nitrogen: NOSmallEmissions

●Hydrogen: Calculate net calorific value

●Carbon: Determination of CO2Emissions

●Sulphur:SOSmallEmissions

●Private laboratory (third-party testing laboratory)

● Cement factory

●Power plant (waste power generation)

● Public laboratories and universities (environmental research)

● National Environmental Monitoring Agency

IS0 21663-Solid Fuel Recovery-Method for Determination of Carbon (C), Hydrogen (H), Nitrogen (N) and Sulfur (S) by Instrumental Method.

Origin: Italy VELP