Biofuel Evaporation Emission Measuring Metergas era one shed

Scalable to multi-channel monitoring12aisle

As biofuel usage increases year by year, demand for biofuel evaporation-related tests has also increased.Biofuels come in various forms of evaporation and emission. For example, the evaporation of ethanol comes from fuel treatment systems, which can evaporate from the tank and penetrate through the fuel hose.Methanol evaporates from the windshield cleaning solution.In addition to ethanol and methanol, the leakage of refrigerant is also an important detection indicator.The new evaporation emission testing requirements need to be achieved through equipment with high sensitivity and strong selectivity.GASERA ONE SHED can simultaneously monitor ethanol, methanol evaporation, and refrigerant leakage without cross-interference. It can be widely used in Sealed House Evaporative Determination: SHED or monitoring.

As part of the vehicle's factory qualified testing procedure, evaporation losses in fuel systems require rigorous and professional certification testing and data quantification.The GASERA ONE SHED test program allows direct monitoring of vehicle evaporation emissions, so it is often used for evaporation emissions tests that new vehicles must perform.Sealed Space Evaporation Determination (SHED) tests monitor evaporation emissions in the automotive industry to ensure compliance with regulatory requirements.

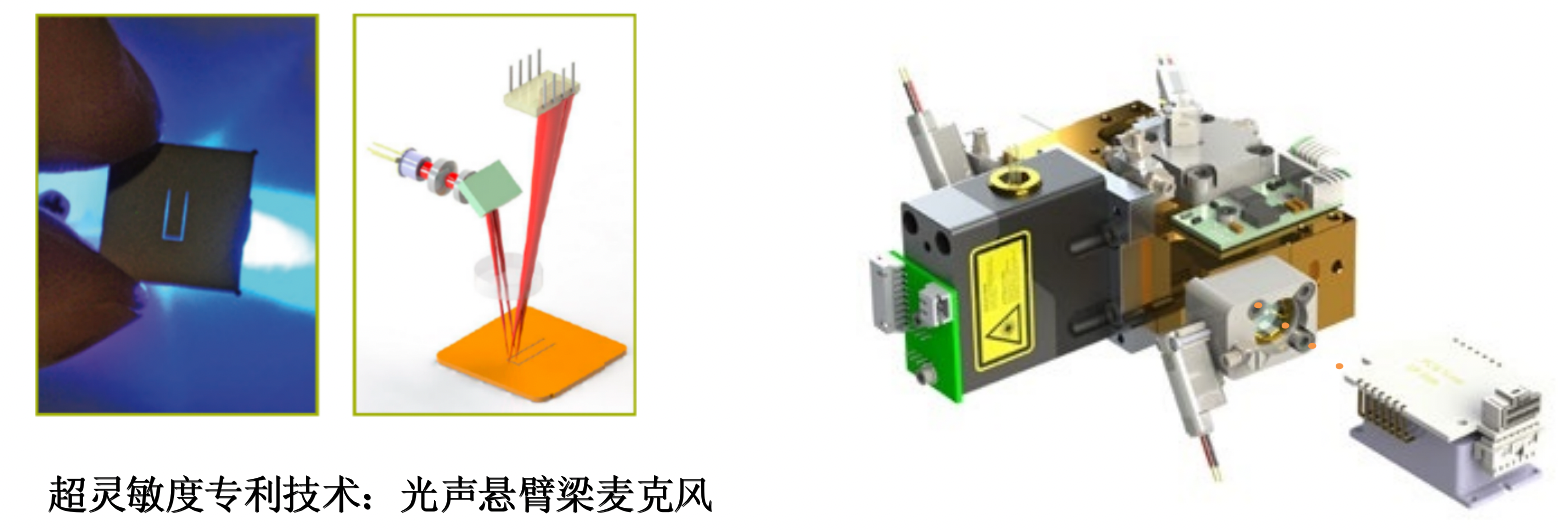

The photoacoustic infrared spectroscopy (PAS) principle used by GASERA ONE SHED is the most practical one of various measurement methods (such as GC-FID, PTR-MS).GASERA ONE SHED is based on the photoacoustic detection technology that improves sensitivity provided by optical microphone solutions.GASERA ONE SHED is an automatic and independent measurement system using an external cavity quantum cascade laser (EC-QCL) as a light source.GASERA ONE SHED provides simultaneous, accurate and sensitive measurements of all target components, ethanol, methanol and refrigerants R-134A and HFO-1234YF, with excellent detection limits.

System Advantages:

üIntuitive user interface

üDrift-free operation through direct absorption measurement

üShort optical paths that provide industry-leading dynamic range through single point calibration

üSelective monitoring of ethanol, methanol, R-134a and HFO-1234yf

üAll measurement gas measurement sensitivity reaches ppb

üIndependent system with built-in gas exchange device

üNo consumables or wet chemicals required

üResponse time user configurable

üHighly selective for ambient background gases and other VOCs

üPhotoacoustic technology is approved by the Environmental Protection Agency and the California Air Resources Commission in the United States

Easy to operate:

gas era one shedEquipped with a high-resolution display and multi-function knobs, it provides users with a simple and intuitive operating interface.

Technical Principles:

The GASERA ONE SHED analyzer is a new measurement system that combines ultra-sensitive cantilever beam enhanced photoacoustic detection with a wide-scanning outer cavity quantum cascade laser source operating within the mid-infrared basic spectral absorption range.This combination provides unparalleled sensitivity for ppb-level monitoring.Due to the wide scanning range, four gases can be measured simultaneously selectively.

Application areas:

Sealed House Evaporation Determination (SHED)

The photoacoustic method is recognized by the Environmental Protection Agency (EPA) and the California Air Resources Commission (CARB) and can be used to directly measure ethanol in the SHED evaporation test.The AK communication protocol enables seamless integration with measurement automation systems.

Refrigerant emissions

Perform quantitative leakage tests on mobile air conditioning equipment to verify compliance with international standards.Even at very low release rates, such as those occurring at low to moderate temperatures, photoacoustic technology provides accurate, fast measurement results and high reproducibility of results.

Air bag/catheter test

The GASERA ONE SHED can be configured for exhaust gas analysis through bag sampling, allowing direct quantitative measurement of trace contaminants in the exhaust gas.

Main technical parameters:

General technical parameters:

ü19’’3U (unit) enclosure for desktop and rack mounting operations

üDimensions: 48.4 x 13.9 x 44cm (W x He x Depth)

üWeight: about 13 kg

üBuilt-in computer with 7-inch WSVGA display

üData storage capacity is sufficient for continuous monitoring at least 1 year with the shortest sampling interval

üTotal internal gas volume 30 ml

üThere are 4 gas-channel interfaces including 2 sample input connections, equipped with user-replaceable dust and small particulate filters

üElectrical connection: Input voltage: 90-264 Vac, 47-63 Hz; Input power: Maximum 75 W

üInterface: Ethernet, USB or other options

üvia USB serial, current message or voltage message.Supports MODBUS and AK protocols

Operation and storage environment parameters:

üOperating conditions: Temperature range: 0 -40℃; Humidity: less than 90%, no condensation; Pressure range: ambient level; Dust/waterproof: IP20 (IEC 529)

üStorage conditions: Temperature range: -20-60℃

üSample gas conditions: Temperature: 0-49℃; Humidity: No condensation; Pressure: 750-1100 mbar; Gas flow: About 1 liter/min during gas exchange.Particulate matter < 1 μm

Measurement related technical parameters:

üResponse time: 40 seconds to several minutes, depending on the user-configurable channel integration time (C.I.T.) and gas exchange program

üDetection limit: Depend on gas and light source, usually from sub-ppb to sub-ppm

üDynamic range: usually 5 orders of magnitude (i.e. 100,000 times the detection limit)

üRepeatability: less than 1% of the measured value under operating conditions of calibration concentration

üAccuracy: Better than 1% at calibration concentration.Limited by calibration gas accuracy

üTemperature stability: The air chamber can be stable to 50℃, and the ambient temperature changes within the operating temperature range will not cause drift

üPressure stability: The sample gas pressure changes within the pressure range will not cause drift

Origin: Gasera, Finland