Technical Solution

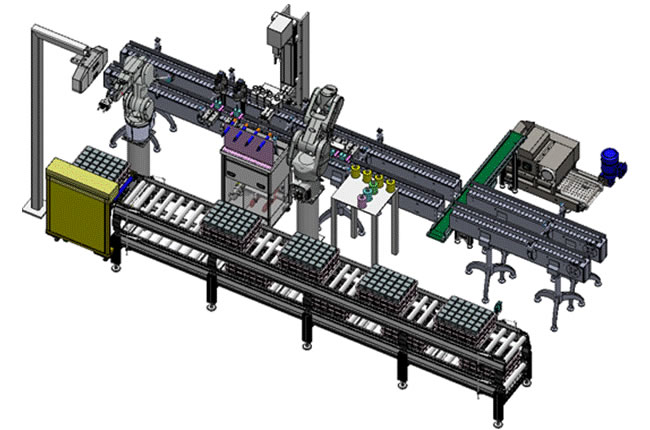

Taking the ABB-IRB series small robot + 3D vision system as the core, referring to the mature experience of the logistics industry, through conveying line transmission, the unpacking and testing of single-pack products in the entire frame is realized, and the testing instruments are interacted with the test instruments to automate the test, andTest data is transmitted to the LIMS system to realize interactive communication of data.

Technical parameters

※ System configuration:

▪ IRB 1200

▪ IRB 1300

▪ Alita system

▪ Fixture

▪ pH detection system

▪ Conveyor system

▪ Extrusion equipment

▪ 3D vision system (including cameras and industrial control machines)

▪ Debugging Service

※System stability: >99.9%

※Processing capacity: can improve the sequence efficiency by 30% (adjusted according to actual projects)

※Reduce personnel: 50% reduction in experimental personnel (adjusted according to actual projects)

Application scenarios

※The factory production line needs to use the finished milk produced on the same day to conduct pH testing as a conveyor line.

※Widely used in scenarios where direct and batch pH detection of products is required

Program display

Place of origin: Shanghai ZQ-Automation