Headquartered in the Netherlands, ASTEC Global provides technical support and services for agriculture and horticulture around the world.There are production bases in the United States, South Africa and China. ASTEC has more than 10 years of experience in seed technology services and has won the trust and support of global customers, and has been committed to the development of new technologies and the application of quality systems in the seed field. With the continuous development and efforts in technology and innovation, ASTEC can provide customers with a variety of solutions, including equipment and technical support, as well as tailor-made production and processing solutions.In terms of seed coating, pelletization and inducing seed treatment technology, ASTEC has also joined hands with its local partner Shanghai Zequan Technology Co., Ltd. to develop new products suitable for the Chinese seed industry. Currently, ASTEC’s main products include seed film coating, shell coating, pelletization and seed induced.In addition, a series of seed quality testing and monitoring products have been launched.Q2 seed vitality detection, seed maturity analyzer (measure ideal harvest time), MarQ seed anti-counterfeiting marking, and Verdict temperature and humidity monitoring system. |

Seed coatingThe coating of field crop seeds is increasing year by year worldwide. Its main function is to improve the operability of sowing and make the same size of seeds in the same batch.In addition, more active active ingredients are added to the seeds while increasing the size and number of seeds.This allows seeds to be protected for a longer period of time after sowing.And compared with conventional field pesticide spraying operations, the active ingredients added by the coating process can make the environment less harmful.This indirectly plays a role in protecting the environment. |

|

The continuous emergence of advanced technology and good production processes has made the field crop seed coating treatment continue to mature technically and economically, and its specific products vary slightly according to different countries and crop varieties. The seeding equipment required for field crops is completely different from the sowing equipment used in vegetable seedling sites. Therefore, compared with vegetable seeds, field crop seeds have unique coating characteristics.For field crops, there are many coating methods and technologies to choose from, but whether the coating plant can be processed in large quantities mainly depends on the actual needs of the field, operability and processing costs. |

|

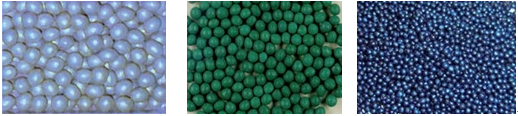

Vegetable seed coating:The materials and processes used for coating and pelletization are usually the same.The difference between the two is that the product specifications are different.In vegetable seed coating processing, the size correction of the seed after coating is relatively looser than pelletization, so the consistency deviation of the final product is slightly higher than that of pelletization.For example, when producing lettuce seed pellets with a specification of 3.5mm, the processed pellets need to be graded and screened to make the pellet size reach the standard between 3.25 and 3.75.At the same time, the weight increases by about 39 times the weight of the initial seed.That is, 1 kg of seeds requires 39 kg of different pelletized materials.The coating uses much less materials than pelleting, so the cost is lower. |

|

Previous seeding equipment had great limitations in its function, such as belt or disc seeders.During the seeding process, each pellet needs to pass through a circular hole with a diameter of 4 mm.For example, lettuce balls with a specification of 350 can pass through a circular hole with a diameter of 4mm very smoothly. In the era of modern technology, more seeding equipment tend to regulate air pressure or manual regulation.The requirements for the shape of the pellets are no longer as strict as before, so that the coating can also replace the pellets in mechanized seeds.So you can choose the weight gain ratio of the coating relative to the pelleted 1 kg of lettuce seeds at will, such as adding 5, 10, 15 or 20 kg of coating materials.At the same time, the purpose of achieving uniform intercrop distances, simplifying operations, and adding effective active ingredients to the seeds with the help of coating material. |

Vegetable seed pelletsSeed pelletization is a series of processes on the surface of the seeds to wrap different material components containing fiber support, bonding, and filling effects.It can improve the appearance of the seeds very well. |

|

During the pelletization process, other different active ingredients can be added like seeds, even phytotoxin products.The finished pellets can also be coated as needed (so as to obtain better fluidity, appearance and color recognition, or plant protection at the seed level) |

|

Pellets can be processed to various sizes according to seeds and pellet types Currently, there are many types of seeding equipment used in different countries and regions.Improving the uniformity of the seed shape can make the seed equipment better.In addition to being more conducive to seeding, pelletization can meet many other seed treatment needs (e.g., the addition of phytoxins, the increase in importance/volume, and the addition and use of other biologically preventive or growth-promoting ingredients). |

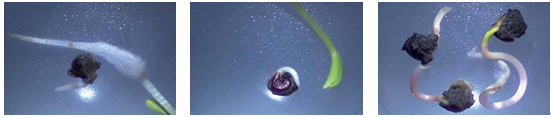

Seed triggerThe R&D Center has been committed to launching new seed technologies that enable seeds to germinate quickly and uniformly in the fields and break dormancy. ASTEC provides you with different types of initiation treatments, soaking seeds is a series of special treatments for cleaning and soaking seeds. Safety & ideal initiation is to initiate the germination process of seeds under controlled conditions. | |

Seed priming can be used for: Solanaceae,Cucurbitae, beet,celery, lettuce,Lettuce, endive,Tobacco, etc. By tree species, | Initiation and comparison

|

Beet Seed Initiation and Control | |

Seed disinfectionSeed disinfection plays an increasingly important role in reducing environmental pressure and increasing yield. With the increasing world population and limited arable land area, the environment is under increasing pressure. Seed disinfection and plant growth regulatorsAddition at the seed level can effectively increase crop yield per unit area of cultivated land and reduce the impact on the environment. | |

| |

At present, we are committed to the development of new products and the testing of different combinations of existing products. Different regions often have different needs for corresponding products.Therefore, regional factors play a decisive role in product performance, applicability, and economics. | |

| |

Seed Selection Technology:The ASTEC R&D team has introduced technology to improve seed quality of seeds with weak live/low bud rate. Seed selection technology can also be combined with seed initiation technology, and the specific combination application depends on the quality of the seed batch. | |

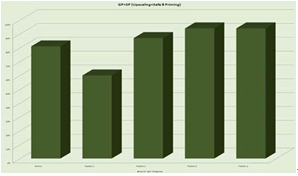

Tomato GP (selected only) |

tomatoGP+SP(Selected+SafetyBCaused) |

Advantages: Improve seed germination rate% Seed selection technology can be used to improve seed wholesale germination rate In particular, the germination rate caused by seed aging after placement decreases. |

Selected germination results for cucumber seeds (Day 10) |

Improve seed vitality: For certain crop varieties, seed selection technology can grade seeds according to the size and weight of the seeds, thereby improving the vitality and uniform bud potential of the seed batch. |

Grade 1 |

Seed Initiation and Selection: The seed batch can also be initiated before/after seed selection, thereby further improving the seed germination speed and uniform bud potential. |

Grade 4 |

Clean Seed selection technology can also replace traditional seed selection methods with high labor consumption. | |